Machine feature:

1.when delivery we will provide the videos for training.

2. More steady and strong equipped bed structure with T-shape thick steel

3. Equipped with 9kw air cooling spindle, , more powerful, enough to cut more thickness materials

4. The auto oiling system, just pushing the handle then can realize the whole machine oiling, very convenient.

5. Dust collector, helping to suck the dust, milling dust, keeping the machine clean.

6. Taiwan SYNTEC control system with industrial control panel.

7. Taiwan HIWIN square guide rail with 30mm diameter, high precision and long life time, rack and pinion transmission, high speed.

8. Vacuum adsorption table with 7.5KW vacuum pump, it can adsorb the materials on the table, more stable when engraving wood doors.

9. servo motor and drivers.

10. Function of re-carving after break point and power off, reducing the materials wasting.

11. Good software compatibility, all kinds of CAD/CAM, such as Typ3, ArtCam, Castmate, UcanCam, Artcut engraving software, Coredraw, etc.

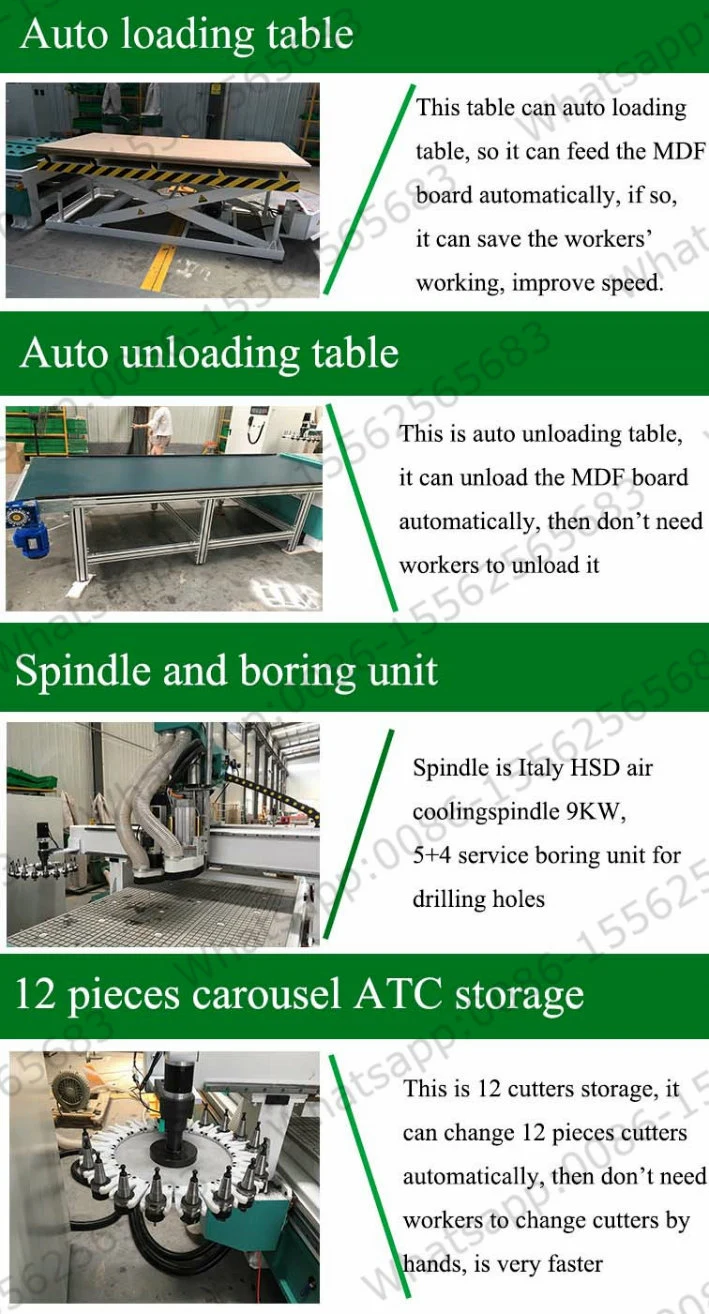

Auto feeding table two set, then it can feed MDF board automatically, it can improve the speed of producing

Main Configuration:

1) Working area: 1300mm*2500mm*300mm

2) Vacuum adsorption table with 5.5KW vacuum pump

3) Cast steel structure thicken to 8mm

4) SYNTEC controller system

5) YASKAWA Servo motors and drivers

6) 9.0 kw HSD ATC spindle

7) Auto tool change with 8 tools

8)Automatic oiling system

9) Taiwan PMI/HIWIN square guide rail with 30mm diameter

10)auto feeding table 2 sets

Application:

1) Furniture: Wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

2) The wood products: Voice box, game cabinets, computer tables, sewing machines table, instruments.

3) Plate processing: Insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, antibate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4) Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Specification

Description | Parameter | ||

| ZK 1325 | zk1530 | Option | |

Working Area (X*Y*Zmm) | 1300x2500x200mm | 1500X3000X200 | According to demands |

Max Moving Speed | 60000mm/min | ||

Max Engraving Speed | 25000mm/min | ||

Frame | Welded Steel | ||

Spindle Power Motor | 9kw | Option:3-12kw | |

Spindle Speed | 12000-24000rpm | ||

The number of knife | 6pcs/8pcs/10pcs/16pcs/20pcs | According to demands | |

The manner to change knife | Circular disk | Option: In-line | |

XYZ traveling positioning accuracy | ±0.04/300mm | ||

XYZ repositioning accuracy | ±0.04mm | ||

Working Voltage | AC380V/50/60Hz,3Ph | ||

Drive Motors | Servo Motors and Drivers | ||

Command language | G code,HPGL | ||

Operating system | SYNTEC control System | ||

Software Compatability | Type3,Ucancam, Artcam Software | ||

Diameter of tools | Φ3.175,Φ6, Φ12.7 | ||

Running Environemt | Temperature: 0°C~45°C | ||

Relative humidity: 30%~75% | |||

Sample pictures

Technical Support:

1. Warranty & Aftersales service:

A)warranty is 1 year

B)24 hour technical support by email or calling

C)User-friendly english manual for machine using and maintaining

2. Rationalization of pre-sales consulting

Welcome to visit our factory

If you have special requirements, of course, we can customize the machine according to your requirements to suit your needs.