Wood Working Machine Four Side Moulder In Wood Planer

Product Description

| Model | HC418E |

| Working width | 20-180mm |

| Working thickness | 8-100mm |

| Min. Working length | 250/500mm |

| Feeding speed | 8-33m/min |

| Spindle speed | 6800r/min |

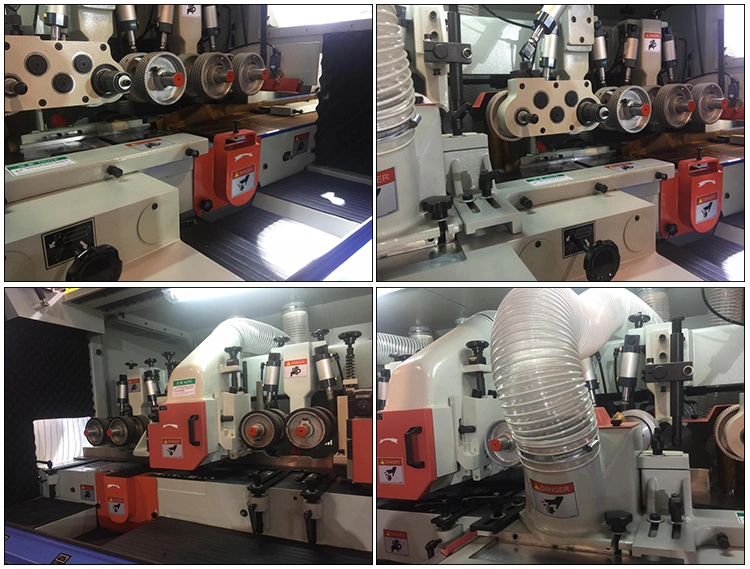

| Spindle quantity & diameter | 4pc & 40mm |

| Cutter diameter | |

| Upper cutter | 105-150mm |

| Bottom cutter | 125mm |

| Right cutter | 115-170mm |

| Left cutter | 115-170mm |

| Machine power | |

| Upper cutter | 5.5kw |

| Bottom cutter | 4.0kw |

| Right cutter | 4.0kw |

| Left cutter | 4.0kw |

| Feeding power | 3.0kw |

| Lifting power | 0.75kw |

| Total power | 21.25kw |

| Voltage | 380v 50hz 3phase |

| Air pressure | 0.6mpa |

| Dust collection port diameter | 4pc*120mm |

| Machine dimension | 3040*1600*1700mm |

| Machine weight | 2800kg |