Yulong 132KW Wood Pellet Making Machinery

Yulong 132KW Wood Pellet Making Machinery-Users show

Yulong 132KW Wood Pellet Making Machinery-structure:

Yulong 132KW Wood Pellet Making Machinery-advantages

Yulong 132KW Wood Pellet Making Machinery-machine model

Yulong 132KW Wood Pellet Making Machinery FAQ

1.Q: General questions to design the production line for you?

A: 1. What is your raw materials? (to confirm mould pressure ratio of machines )

2. What is the moisture content of your raw material?

3. How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 13-15%. And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Will you send engineers to install the machines?

A: Of course. Our company has professional installation engineers team and specialized after-sale service team. When the machines arrive your factory, we will send our installation engineers to your factory Our engineers will Guide you to install the machines and training your workers how to operate the machines and maintain the machine.

4. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Why do we choose your company?

1.We specialize in pellet machine manufacture,which are superior quality with competitive price.Technology research and development since 1998, CE and ISO9001 are certificated;

2.We have agents in many countries who can supply you good after-sale service.

3.We have perfect and professional after-sale department which can arrange technician engineer to guide installation and train your workers to operate machines.

4.We have independent research and develop department which will design machine to meet your special raw materials need.

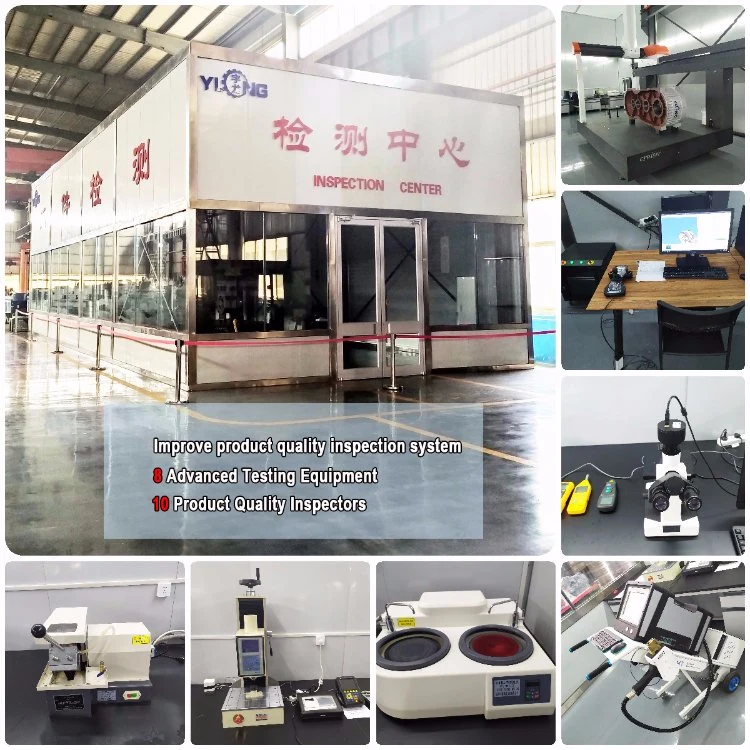

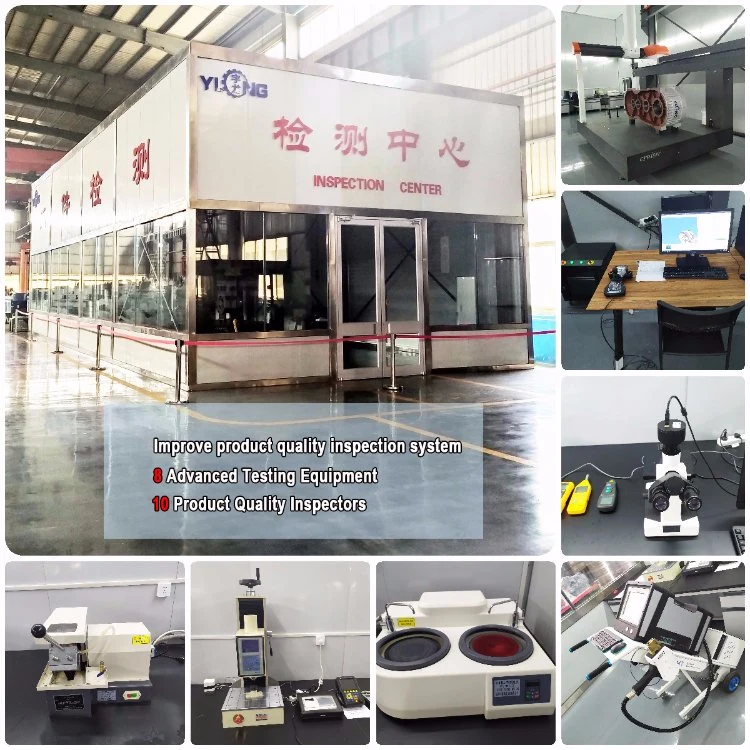

5.We have strict quality control system which will promise you good machine.

Yulong 132KW Wood Pellet Making Machinery-company strength

| Company Overview | |

| Register Time | 1998-2007-HUA Long 2007-November 5th , 2018-Zhangqiu Yulong Machine Co., Ltd Since November 6th, 2018-Shandong Yulong Machine Co., Ltd |

| Registered capital | CNY 10Million |

| Company Area | >73000m2 |

| Employee | >200 |

| Company Type | Manufacturer and trading company |

| Main products | Pellet Machine, hammer mill, dryer, chipping machine, pellet cooler, packing machine etc and related auxiliary equipment |

| Branches | Malaysia, Thailand, Indonesia |

| Agent | Poland, Bulgaria, Netherlands, Spain |

| Slogan | Develop green energy for the benefit of human society |

| Vision | Create a first-class brand, build a century-old of enterprise |

Yulong 132KW Wood Pellet Making Machinery-structure:

Yulong 132KW Wood Pellet Making Machinery-advantages

| 1 | Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Reduce operating costs. |

| 2 | Vertical ring die, feeding vertically, the raw materials can follow to the pellet machine pelleting room directly. |

| 3 | Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually. |

| 4 | Ring die fixed, main shaft vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably. |

| 5 | Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity. |

| 6 | Extremely compact kick-out device, more stable during working. |

| 7 | The cover of kick-out device adopt 304 stainless steel, anti-wear and corrosion -resistant. |

| 8 | The cover of kick-out device to be pressed one time forming, high strength. |

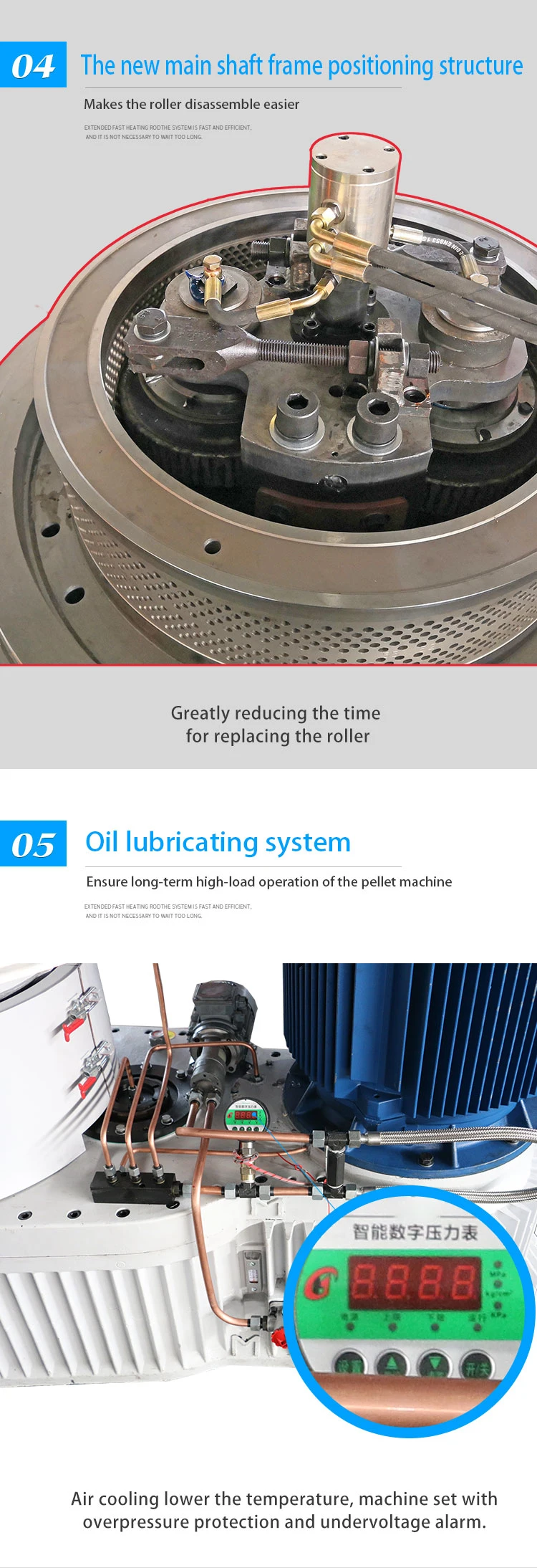

| 9 | Two sets lubrication system--one is lubrication pump to lubricate rollers, the other is lubrication pipe to lubrication main shaft and gear box which ensure the pellet machine can work long time. |

| 10 | Thin oil lubrication cooled by air, and equipped with overpressure protection and underpressure alarm, real-time display of circulating pressure, to ensure long-term high load operation of pellet mill. |

| 11 | The position of pellet outlet and kick-out reducer can be adjusted according to customers' wishes or factory field situation. |

| 12 | The main shaft adopt high stiffness load-bearing structure, diameter increased 15%. And the load-bearing surface of main shaft bearing added 1 time. More stable operation and lower failure rate, aimed to make the pellet machine output higher. |

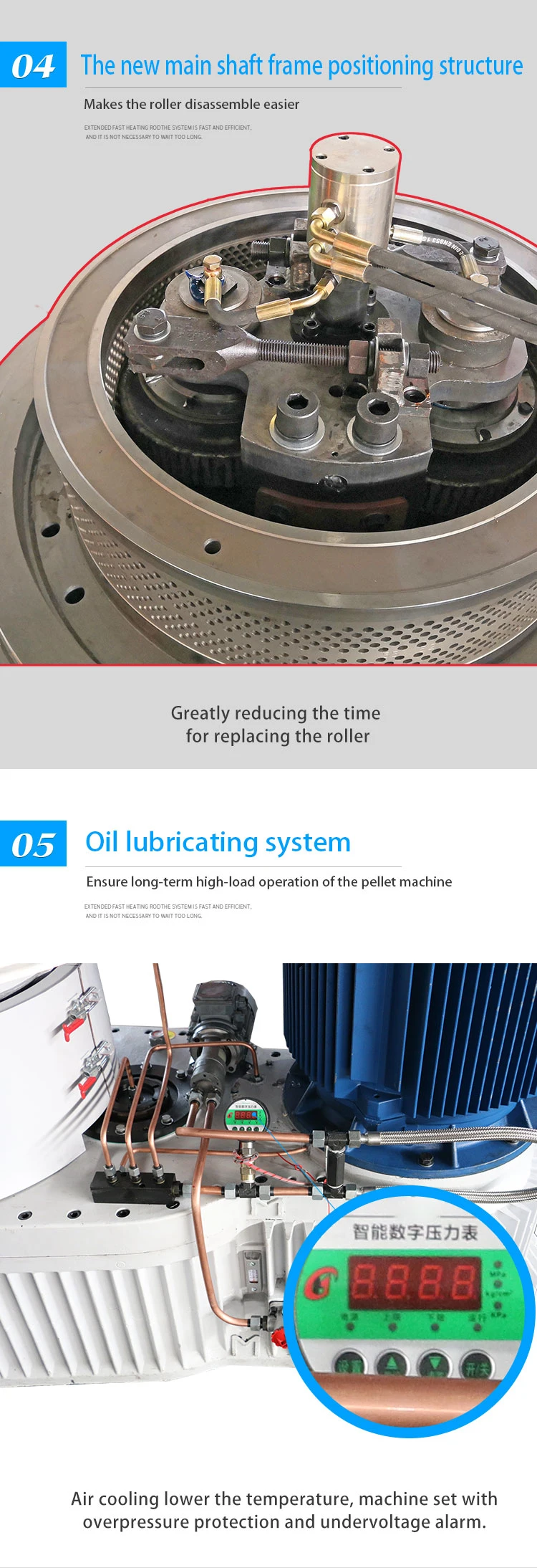

| 13 | The new positioning structure of main shaft supporting frame makes it easier to disassemble the roller and greatly reduces the time for users to replace the roller. |

| 14 | The new pressure roller surface adopts the technology of the robot surfacing alloy which extend the service lifetime of the roller. |

| 15 | The mould all used high-end wear-resistant stainless steel plus advanced vacuum furnace quenching technology, hardness of surface and inside is the same. |

| 16 | The mould hole is machined by ultra-high speed gun drill, and the it can be used after grinding slightly. |

| Model | Power | Capacity | Weight |

| Fifth-generation Ring Die Pellet Mill | |||

| XGJ560 | 90+1.5+0.37+0.37+2.2 | 1-1.5T/H | 5.3T |

| XGJ850 | 220+3+0.55+0.55+3 | 2-3T/H | 14.8T |

| Seventh-generation Ring Die Pellet Mill | |||

| XGJ560 | 132+2.2+0.37+0.55+2.2 | 1.5-2T/H | 4.5T |

| XGJ850 | 220+4+0.55+0.55+3 | 2.5-3.5T/H | 8.5T |

1.Q: General questions to design the production line for you?

A: 1. What is your raw materials? (to confirm mould pressure ratio of machines )

2. What is the moisture content of your raw material?

3. How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 13-15%. And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Will you send engineers to install the machines?

A: Of course. Our company has professional installation engineers team and specialized after-sale service team. When the machines arrive your factory, we will send our installation engineers to your factory Our engineers will Guide you to install the machines and training your workers how to operate the machines and maintain the machine.

4. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Why do we choose your company?

1.We specialize in pellet machine manufacture,which are superior quality with competitive price.Technology research and development since 1998, CE and ISO9001 are certificated;

2.We have agents in many countries who can supply you good after-sale service.

3.We have perfect and professional after-sale department which can arrange technician engineer to guide installation and train your workers to operate machines.

4.We have independent research and develop department which will design machine to meet your special raw materials need.

5.We have strict quality control system which will promise you good machine.

Yulong 132KW Wood Pellet Making Machinery-company strength