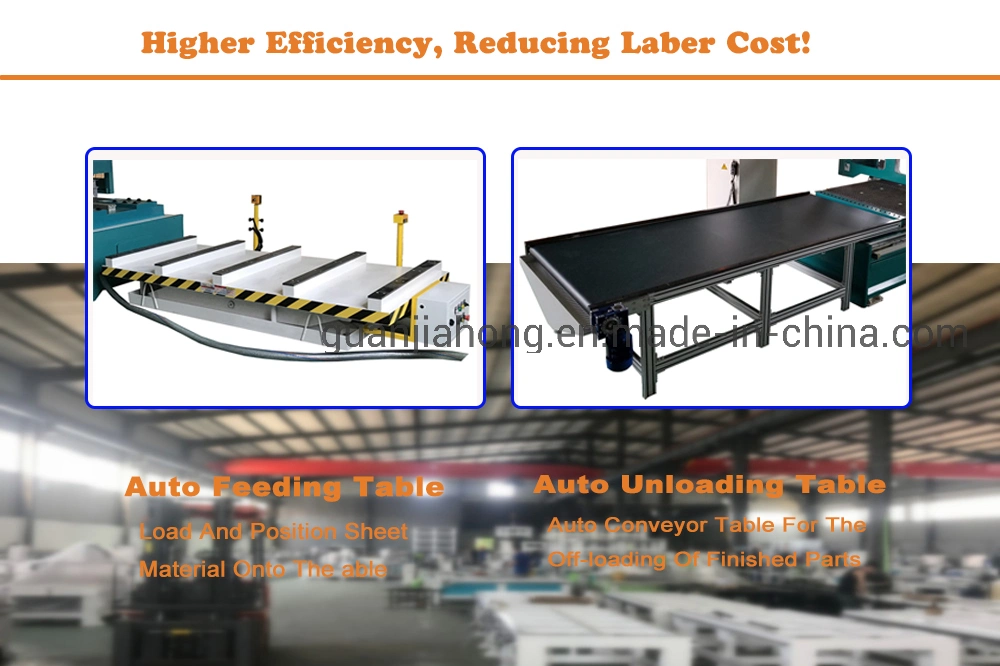

1.All IN ONESTEP-Automatic loading, cutting, drilling, slotting, automatic offloading.

2.Automatic loading and off-loading system

The Suction Cup Loading Device and Integrated Vacuum Cleaning System is standard on the Full

Line CNC Router. The Integrated Vacuum Cleaning System ensures that all dust and debris is

removed from the machine table prior to loading the next sheet. The industrial strength vacuum

cups will load and position sheet material onto the table top without scratching the surfaces and

aligns them perfectly against the pop up pins.

3.Humanizing design of the machine control interface,very simple to operate, requiring only minimal

training of operator, do not need specialized operation technical personnel, high efficiency.

Applicable industry: wood furniture , panel furniture,wooden crafts processing industry, suitable for large panel cutting,large relief carving products and large carpentry engraving.

Applicable material: solid wood panel, artificial board,Acrylics,PVC,MDF,Plexiglass.

| NO | Index | Index | Parameter |

| 1 | Traveling | X axis | 1300mm |

| Y axis | 2500mm | ||

| Z axis | 200mm | ||

| 2 | Working area | 1220x2440mm | |

| 3 | Accuracy | Working accuracy | ≥0.1mm/300mm |

| Traveling Accuracy | ≥±0.2mm/300mm | ||

| Reposition accuracy | ≥±0.05mm/300mm | ||

| 4 | Transmission | X axis | Helical Rack |

| Y axis | Helical Rack & Double motors | ||

| Z axis | Screw | ||

| 5 | Speed | Max Rapid | 50000mm/min |

| Max working speed | 15000mm/min | ||

| 6 | Spindle | Spindle power | 9KW |

| (Water-cooling) | Spindle speed | 18000r/min | |

| 7 | Drive mode | Servo | |

| 8 | Working voltage | AC220/50HZ | |

| 9 | Command language | G Code | |

| 10 | Operation system | Syntec 6MB |