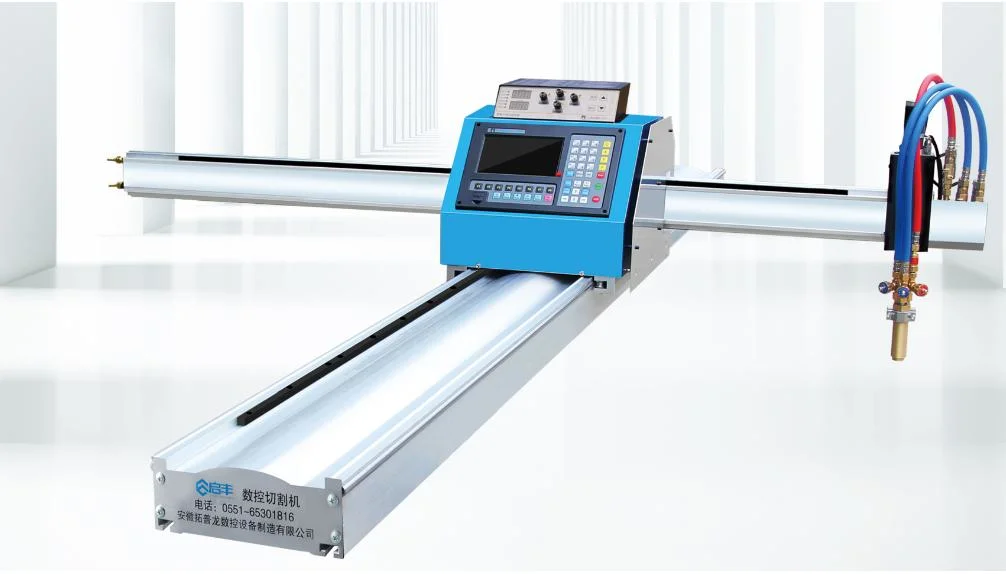

Portable CNC cutting machine

The portable CNC cutting machine has a small and exquisite and micro structure. It is an ideal upgrade product to replace handheld flame cutting equipment, handheld plasma cutting devices, profiling cutting machines and semi-automatic cutting carts. The use is as flexible and convenient as the cutting trolley, and it can be moved at will without occupying a fixed site. It is a numerical control equipment specially used for sheet metal blanking. It is suitable for internal and external cutting, and can cut various metal materials according to any pattern. The roughness of the cut can reach 25 (V3), and the cut surface after cutting generally does not require surface processing. It has the advantages of high degree of automation, easy use, high precision, high reliability, low price, and very simple operation and maintenance. It is widely used in machine tool manufacturing, petrochemical equipment, light industrial machinery, shipbuilding, pressure vessels, engineering machinery, and mining Machinery, electric power, bridge construction, aerospace, steel structure and other industries.

Mechanical characteristics:

1. The base is assembled by high-strength aluminum alloy, with good stability, no deformation, and beautiful appearance.

2. The new combined chassis structure design, the cross arm and the main console, as well as the mechanical and numerical control parts can be decomposed and combined. The outside of the case is equipped with a USB interface, a control cable interface, and a plasma arcing interface to ensure the stable operation of the machine.

3. The beam is made of special aluminum alloy industrial profiles, which is light in weight and does not deform. The beam can be disassembled, which is convenient for on-site transfer, packaging and transportation, and ensures that the verticality of the beam does not change

4. A more user-friendly main console directly faces the cutting site, which greatly broadens the working perspective

5. The walking part adopts precision non-backlash gear and rack drive to ensure accuracy and eliminate backlash.

6. The motor adopts stepper motor drive technology, and adopts high subdivision drive, high precision and stable operation

7. Crossbeam. The upper part of the stainless steel square tube is added to facilitate the fixing of the plasma cable and is more user-friendly.

Product performance specification:

Main accessories:

The portable CNC cutting machine has a small and exquisite and micro structure. It is an ideal upgrade product to replace handheld flame cutting equipment, handheld plasma cutting devices, profiling cutting machines and semi-automatic cutting carts. The use is as flexible and convenient as the cutting trolley, and it can be moved at will without occupying a fixed site. It is a numerical control equipment specially used for sheet metal blanking. It is suitable for internal and external cutting, and can cut various metal materials according to any pattern. The roughness of the cut can reach 25 (V3), and the cut surface after cutting generally does not require surface processing. It has the advantages of high degree of automation, easy use, high precision, high reliability, low price, and very simple operation and maintenance. It is widely used in machine tool manufacturing, petrochemical equipment, light industrial machinery, shipbuilding, pressure vessels, engineering machinery, and mining Machinery, electric power, bridge construction, aerospace, steel structure and other industries.

Mechanical characteristics:

1. The base is assembled by high-strength aluminum alloy, with good stability, no deformation, and beautiful appearance.

2. The new combined chassis structure design, the cross arm and the main console, as well as the mechanical and numerical control parts can be decomposed and combined. The outside of the case is equipped with a USB interface, a control cable interface, and a plasma arcing interface to ensure the stable operation of the machine.

3. The beam is made of special aluminum alloy industrial profiles, which is light in weight and does not deform. The beam can be disassembled, which is convenient for on-site transfer, packaging and transportation, and ensures that the verticality of the beam does not change

4. A more user-friendly main console directly faces the cutting site, which greatly broadens the working perspective

5. The walking part adopts precision non-backlash gear and rack drive to ensure accuracy and eliminate backlash.

6. The motor adopts stepper motor drive technology, and adopts high subdivision drive, high precision and stable operation

7. Crossbeam. The upper part of the stainless steel square tube is added to facilitate the fixing of the plasma cable and is more user-friendly.

Product performance specification:

| Model specification | TPL-1625(Portable) | TPL-1630(Portable) | TPL-1640(Portable) |

| Cutting range | 1600*2500(mm) | 1600*3000(mm) | 1600*3000(mm) |

| Idle speed | 7m/min | ||

| Cutting speed | 2-6m/min | ||

| Cutting thickness | 1~30mm (plasma) (Note: depends on the size of the optional cutting power supply), 5~≥100mm (flame) | ||

| Line drawing accuracy | 0.2m | ||

| Operating Voltage | AC220/380V10% 50Hz | ||

| Rated power | 300W(Does not include plasma power supply and air compressor) | ||

| Current adjustment method | Continuously adjustable | ||

| Air compressor specifications | Recommended air consumption≥180L/min, 6kg/cm2 | ||

| Plasma power | According to product requirements, customers can choose plasma power supply, or purchase power supply by themselves. Take 100A as an example, AC380V, 10% 50Hz, 20KVW, load rate 60% | ||

| Hand-held cutting gun |  |

| system |  |

| 57GB stepper motor driver |  |

| Cutting machine relay control board |  |

| 24v combination switching power supply |  |

| 86 motor drive |  |

| 110 three-phase motor drive |  |